Pars Pigment & Catalyst

Our PARHYDCAT®

PARHYDCAT® MC 520, NHDS Catalyst

is Co-Mo catalyst used for desulfurization and denitrification on of hydrocarbons cuts including naphtha and kerosene, It is based on y-AI2O3 as carrier, and Co-Mo as active components. It has the characteristics of large specific surface area, centralized pore distribution, high hydro desulfurization activity as well as good olefin saturation performance and more. This catalyst is suitable for hydro desulphurization of light distillates.

PARHYDCAT® MC 510, GHDS Catalyst

is based on alumina as the carrier and Ni-Mo as active components. This catalyst is used for the deep hydro desulfurization and hydro treatment of diesel and kerosene fraction. This catalyst shows a high denitrating activity, a high activity in hydrogenation of Polycyclic Aromatic Hydrocarbons, and also a high desulfurizing activity. Using MC 510, you can get hydrotreated fractions, which meet the Standard requirements of Euro-4 and Euro-5.

PARHYDCAT ®MC 530, Hydrogenation Catalyst (Natural gas HDS)

is a catalyst, which based on y-AI2O3 as carrier, and Co-Mo as active components. This catalyst is suitable for hydro desulfurization of refined gas or natural gas.

PARHYDCAT® MC 600, used for hydrofining of hydrocarbon

Cuts including naphtha and kerosene. PARHYDCAT® MC 600, as main catalyst, is a distillate hydro desulfurization catalyst. It is based on y-AI2O3 as carrier, and Co-Mo as active components. This hydrotreating catalyst for naphtha fraction produce under license of Research Institute of Petroleum Industry (RIPI).

PARHYDCAT® PC 520, protecting HDS Catalyst

is based on large pore AI2O3 as carrier and Mo-Ni as activity components. The exterior is Raschig ring, which as appropriate porosity. PARHYDCAT® PC 520 has the characteristics of high demetalling activity and low bed pressure drop.

PARHYDCAT® PC 530, protecting HDS Catalyst

is based on large pore AI2O3 as carrier and Mo-Ni as activity components. The exterior is sphere with ridges, which have appropriate porosity. It has the characteristics of high demetalling activity and low bed pressure drop.

PARHYDCAT® PC302 HDS Protecting Catalyst

PARHYDCAT® PC302 protective catalyst with higher strength and good chemical stability, higher impact resistance, larger porosity, higher capacity of scale, filling in the top of the bed, providing the larger pore and void volume, effectively removing and bearing mechanical impurities in the feed. It can control the catalyst bed pressure drop rising, prolong the running cycle of the device.

PARHYDCAT® PC304 Protecting Catalyst

PARHYDCAT® PC304 is a hydrogenation of metal removal catalyst, which used modified α-A1203 as support, nickel and molybdenum as active components. The catalyst has the characteristics of high strength, large pore volume, strong carbon resistance and scale capability. It can remove metal ions, especially iron ions, and can accommodate and remove mechanical impurities in the feed oil effectively. It can replace the ceramic ball and porous fillers to fill the upper part of the hydrogenation catalyst bed completely or partially, to avoid coking and compaction of the below hydrogenation catalyst. It can control the catalyst bed pressure drop rising, prolong the running cycle of the device.

PARHYDCAT® PC305 Protecting Catalyst

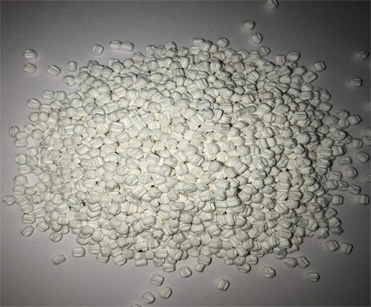

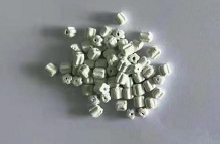

PARHYDCAT® PC305 is a kind of protective catalyst for hydrogenation, used modified Al2O3 as support and more nickel and molybdenum as active components with different form (sphere with a central hole, gearwheel). The catalyst has the characteristics of large pore size, large porosity, strong scale capacity etc., which can remove little arsenic, organic silicon, copper, lead and other impurity metal ions in the feed oil effectively and deposit them into its own pore canal. It is suitable for loading into the upper bed of naphtha hydrogenation treatment unit to protect the below hydrogenation catalyst and avoid the deactivation of the hydrogenation catalyst by poisoning. It can prolong the operation cycle of the unit effectively.

PARHYDCAT® PC307 Protecting Catalyst

PARHYDCAT® PC307 is a kind of protective catalyst for hydrogenation, used modified Al2O3 as support and nickel and molybdenum as active components. The catalyst has the characteristics of large pore size, large porosity, strong scale capacity etc., which can remove little arsenic, organic silicon, copper, lead and other impurity metal ions in the feed oil effectively and deposit them into its own pore canal. It is suitable for loading into the upper bed of naphtha hydrogenation treatment unit to protect the below hydrogenation catalyst and avoid the deactivation of the hydrogenation catalyst by poisoning. It can prolong the operation cycle of the unit effectively.