Pars Pigment & Catalyst

Our PARMOCAT®

PARMOCAT®L30

PP&C Co. succeed to produce petroleum fractions treatment catalyst for removal of mercaptans under the brand name "PARMOCAT® 634L30" (replacement for Merox brand name of UOP which is known in Iranian market) by support of NIORDC Manager. PARMOCAT® catalyst uses for chemical treatment of petroleum fractions by removal of sulfur presented as mercaptan or direct conversion of mercaptans to disulfides (sweetening). It is used for liquid phase treating of liquefied petroleum gas (LPG), natural gas liquids (NGL), naphtha, gasoline, kerosene, jet fuels, diesel fuels and heating oils.It can also be used to sweeten natural gas, refinery gas and synthetic gas in combination with conventional pre-treatment and/or post-treatment processes. There are several versions for convention of mercaptans to disulfides that the fix bed process is common. This catalyst has been consumed in some different oil refineries and its quality approved, too. Today, PARMOCAT® use in all oil Refineries and the capacity of our production unit is 15 ton/year. The quality of product has confirmed by Kermanshah, Shiraz, Abadan and Bandar Abbas Oil Refinery.

Our PARMOGAS®

Mercaptan Oxidation Catalyst [Alternative for Demercaptanization of Distillate Demercaptanization of Condensate (DMD-DMC), UOP Merox and Axens Sulfrex]

has the high capability of decreasing of mercaptans and sulfur compounds in hydrocarbon cuts such as oil distillate, gas condensate, light oil; naphtha and gasoline up to environmental standards.

Catalyst preparation, technology licensing and know- how are developed in the Research Institute of Petroleum Industry (RIPI). Catalyst production license is transformed to Pars Pigment and Catalyst Company (PP&C), based on contract between two parties.

The high scale production has been successfully done by the PARS PIGMENT AND CATALYST COMPANY (PP&C).

The DMD process with the production of demecaptanization. catalyst under brand-name PARMOGAS® in partnership with the RIPI has been commercialized in PP&C.

RIPI's Capability

+ Semi-industrial pilot plant for DMIC-DMD with the capacity of 20 barrels/day

+ Fully equipped laboratory with bench scale pilot plants

+ Licensing and engineering of several industrial sweetening plants for LPG and gas condensate

PP&C's Capability

+ Large Scale Production facilities for PARMOGAS®.

+ Quality Control Labs.

Physical & chemical properties of PARMOGAS®

|

Item

|

Characteristic

|

Unit

|

Value

|

|---|---|---|---|

|

1

|

Chemical Formula

|

-

|

Sulfonated Cobalt Phthalocyanine

|

|

2

|

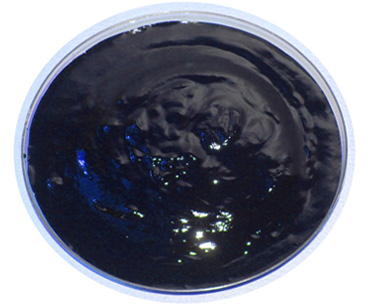

Appearance

|

-

|

suspended liquid, dark blue color without smell or sometimes little ammonia smell

|

|

3

|

Co Content

|

Wt.%

|

5

|

|

4

|

Density

|

g/cm3

|

1.05-1.2

|

|

5

|

Reduction of Mercaptan in Condensate

|

ppm

|

˂50*

|

|

6

|

Reduction of Mercaptan in Naphtha and C5+

|

ppm

|

˂30*

|

|

7

|

Reduction of Mercaptan in LPG

|

ppm

|

˂5*

|

*Based on Feed characterization and process scheme.

Package and Points for Attention

Two and half liter or 4 liter PE container, each of 6 packages is in one pallet shirring according to the customers demand, it may supply in customer packaging options.