Our Products

Used in Petrochemical Industries :

Hydrogenation Catalyst (PARHYDCAT®)

Natural gas HDS catalyst (PARHYDCAT® MC530) is a kind of distillate HDS catalyst. It prepared by using mesoporous γ-Al2O3 as carrier and Co-Mo as active components. It has the characteristics of high specific surface area, centralized pore distribution, high HDS activity as well as good Olefin Saturation performance, etc. This catalyst is suitable for hydrodesulphurization of refinery gas or natural gas.

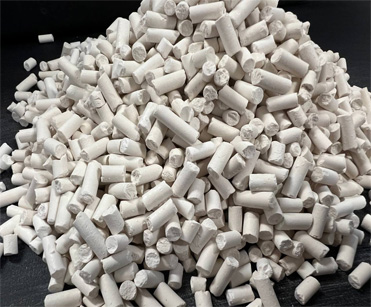

Desulphulizer Catalyst (PARZICAT®)

Zinc Oxide adsorbents for sulfur removal from hydrocarbon process feeds are accepted method in industry for pre-treatment of feed gas to steam reforming units. The efficiency and capacity of the current range of Zinc Oxides desulfurizing catalyst allows sulfur to be removed from the process feed on a continuous basis and to the levels necessary to protect the downstream nickel reforming catalysts.

Primary Reformer Catalyst

Steam reforming is the most widespread process for the generation of hydrogen-rich synthesis gas from light carbohydrates. The feed materials natural gas, liquid gas or naphtha are endothermically converted with water steam into synthesis gas in catalytic tube reactors. Process heat as well as flue gas are used for the steam generation. PARSYNSCAT® 412Q/413Q catalyst is a group of nickel as the active component. It is suitable for natural gas as raw material, steam conversion to produce industrial hydrogen, ammonia synthesis gas, and methanol synthesis gas....PARSYNSCAT® 412Q is loaded in front part of tube. PARSYNSCAT® 413Q is loaded in back of tube. Both are loaded in a certain proportion or adjusted according to the actual situation. PARSYNSCAT® 412Q/413Q catalyst has the characteristics of large geometric surface, small bulk density, good heat transferring, high activity, small pressure drop and large range of operation conditions.

Secondary Reformer Catalyst

PARSYNSCAT® 201/202 catalyst is a group of nickel as the active component, high temperature alumina and aluminum-calcium as the carrier of high temperature sintering type natural conversion catalyst, it is suitable for oil field gas or natural gas as raw material, steam conversion to produce industrial hydrogen, ammonia synthesis gas, methanol synthesis gas, directly metallurgical reduction gas of high temperature reformer. It is also suitable for the process of oxygen-rich partial oxidation and intermittent conversion to syngas. 201 is a heat-resistant catalyst, loaded in front part of tube. 202 is a high activity conversion catalyst, loaded in back of tube proportionally....Shift Conversion Catalysts The second important reaction in a steam reforming plant is the shift conversion reaction: CO+H2O→CO2+H2 Two basic types of shift catalyst are used in steam reforming plants: iron/chrome high-temperature shift catalysts and copper/zinc low-temperature shift catalysts. High-temperature shift catalysts operate in the range of 315–430°C (600–800°F) and consist primarily of magnetite (Fe3O4) with three-valent chromium oxide (Cr2O3) added as a stabilizer. The catalyst is usually supplied in the form of ferric oxide (Fe2O3) and six-valent chromium oxide (CrO3) and is reduced by the hydrogen and carbon monoxide in the shift feed gas as part of the start-up procedure to produce the catalyst in the desired form. However, caution is necessary since if the steam/carbon ratio of the feedstock is too low and the reducing environment is too strong, the catalyst can be reduced further to metallic iron. Metallic iron is a catalyst for Fischer-Tropsch reactions, and hydrocarbon derivatives will be produced. Low-temperature shift catalysts operate at temperatures on the order of 205–230°C (400–450°F). Because of the lower temperature, the reaction equilibrium is more controllable, and lower amounts of carbon monoxide are produced. The low-temperature shift catalyst is primarily used in wet scrubbing plants that use a methanation for final purification.

High-Temperature Shift Catalyst

HTSC Catalyst PARSHICAT® 101 is a High temperature CO shift conversion (HTSC) catalyst specifically for the production of hydrogen, ammonia syngas, methanol syngas etc. in hydrocarbon steam reforming process.

Low-Temperature Shift Catalyst

PARSHICAT® B-204 is a kind of energy-saving catalyst produced by using international state-of-art technology. PARSHICAT® B-204 has the characteristics of low temperature, high activity, low bulk density and high operating strength after reduction as well as suitable to be used under low steam/gas ratio process condition. The perfect feature of the PARSHICAT® B-204 is the high selectivity, which can inhibit alcohol forming efficiently. It is used in the downstream of the high temperature shift catalyst to further shift the CO in rich hydrogen flow and to produce more hydrogen through the following reaction:...

CO+H2O=CO2+H2+41.9KJ/mol

Moreover, purify the hydrogen simultaneously.

PARSHICAT® B-204 can inhibit properly the following side reaction caused by decreasing the steam/gas ratio:

nCO+2nH2=CnH2n+1OH+(n-1)H2O+H

2CO=CO2+C+H

There is no free water in PARSHICAT® B-204 finished catalyst, so there is no need to remove water in the course of warming up reduction.

Methanation Catalyst

Methanation process is a convenient and economical method for gas purification, which can reduce the carbon oxide to a low residual content of 10-6 (V/V). Under a proper unit design and operation condition of methanator reactor, The outlet of CO + CO2 is usually easy reduced to less than 10×10-6 (V/V). In addition, the service life can reach more than 5 years in large hydrogen and ammonia production units.

Ammonia Synthesis Catalyst

The main components of A110 ammonia synthesis catalyst are composed of some microelement such as iron oxide (Fe3O4), alumina (Al2O3), potassium oxide (K2O), calcium oxide (CaO). A110 ammonia synthesis catalyst is easily damped in the air, which results in the precipitation of soluble potassium salts and decreases its activity. It becomes a highly active catalyst after reduction with hydrogen-nitrogen mixture in the synthesis tower. The reduced A110-H catalyst will burn rapidly and lose its activity if exposed to the air. The main poisons against catalyst are sulfur, phosphorus, arsenic and oxygenated compounds. Carbon monoxide, carbon dioxide, water vapor etc. can cause catalyst poisoning temporarily, while oil and sulfide can cause poisoning permanently.

PARTONIT® 512 highly active acid clay

PARTONIT®️ 512 is a highly active acid clay used in a wide scope of applications base on absorption. It is produced by acid activation of calcium bentonite in our complex since 2014.

PARTONIT®️ 512 is a specialized material with a highly porous inner structure and a multitude of active sites.

PARTONIT®️ 512 is very suitable for absorption and treatment in a fixed bed reactor like the catalytic treatment of BTX (benzene, toluene, and xylene) feed and gas oil stocks and designed for Nitrogen adsorption from extracted benzene, toluene or xylene. It shows higher adsorptive capacity and selective for making colorless and odorless.