Our Products

Used in Oil and Gas Refinery Industries :

Hydrogenation Catalyst (PARHYDCAT® )

Natural gas HDS catalyst (PARHYDCAT® MC530) is a kind of distillate HDS catalyst. It prepared by using mesoporous γ-Al2O3 as carrier and Co-Mo as active components. It has the characteristics of high specific surface area, centralized pore distribution, high HDS activity as well as good olefin saturation performance, etc. This catalyst is suitable for hydrodesulphurization of refinery gas or natural gas.

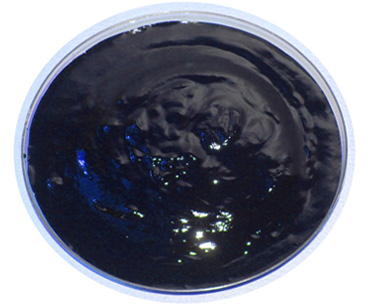

PARMOCAT®L30

PP&C Co. succeed to produce petroleum fractions treatment catalyst for removal of mercaptans under the brand name "PARMOCAT® 634L30" (replacement for Merox brand name of UOP which is known in Iranian market) by support of NIORDC Manager. PARMOCAT® catalyst uses for chemical treatment of petroleum fractions by removal of sulfur presented as mercaptan or direct conversion of mercaptans to disulfides (sweetening). It is used for liquid phase treating of liquefied petroleum gas (LPG), natural gas liquids (NGL), naphtha, gasoline, kerosene, jet fuels, diesel fuels and heating oils.

PARMOGAS®

Mercaptan Oxidation Catalyst [Alternative for Demercaptanization of Distillate Demercaptanization of Condensate (DMD-DMC), UOP Merox and Axens Sulfrex] has the high capability of decreasing of mercaptans and sulfur compounds in hydrocarbon cuts such as oil distillate, gas condensate, light oil; naphtha and gasoline up to environmental standards. Catalyst preparation, technology licensing and know- how are developed in the Research Institute of Petroleum Industry (RIPI). Catalyst production license is transformed to Pars Pigment and Catalyst Company (PP&C), based on contract between two parties.

PARALCAT®

Sulfur Recovery Catalyst (Claus catalyst) was produced in our complex in 2010. Sulfur recovery refers to the conversion of hydrogen sulfide (H2S) to elemental sulfur. Hydrogen sulfide, a byproduct of crude oil and natural gas processing, is recovered and converted to elemental sulfur by the Claus process. The process consists of multistage catalytic oxidation of hydrogen sulfide that each stage consists of special catalyst.